You may not know it, but precision die-casting products are everywhere around us, learn about the applications of die-castings. Die-casting has had a long history since it was first invented in 1839 for the printing industry.

Why is precision die casting popular?

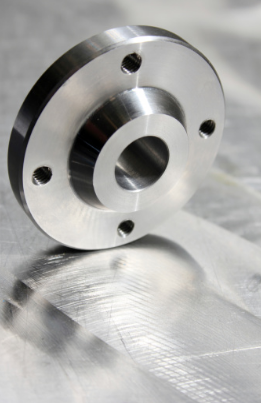

This technique has come a long way since 1839 and has now become a huge part of our everyday lives, you can read more on the history here. The main reason why precision die-casting is popular is that no other mass production technique can provide such complicated geometries and designs with close tolerances and minimal machining. Modern die casters can produce high-strength, precise die castings with short production cycles. You can learn more about precision die-casting vs machining here https://www.cimisf.com/precision-diecasting/precision-die-cast-vs-machining/. The primary advantages of precision die casting are low unit costs, high physical performance, and consistent parts.

The die casting industry is also very environmentally friendly as they are heavily based on recycling. Around 95% of the aluminum die casts made in North America are made from recycled aluminum. All the scraps from casting runs are melted and reused in the future for other parts. This helps keep the aluminum waste to less than 1%.

Why should you choose CIMI?

For over 30 years CIMI has been providing some of the most respected companies throughout North America with superb quality casting solutions.

CIMI specializes in high-precision, tight-tolerance castings, providing completely finished turnkey parts. We are also capable of doing complex assemblies according to our customer’s requirements.

CIMI specializes in Aluminum and Zinc die castings. Other materials are also available. Here are some of our specialties:

– Consistent tolerances up to 0.001” through machining processes.

– Precision diecastings with complicated geometries.

– Surface treatments and finishes including

Chromate, Plating, Anodizing, Powder Coating and Painting.

– Impregnation and testing to the pressures required.

CIMI makes all the tools and fixtures in-house to ensure quality and functionalities. This capability also enables us to efficiently manage tools and fixtures for maintenance and repairs to minimize downtime. At the same time this complete control flow allows us to reduce the turnaround time required for changes or revisions.

CIMI is dedicated to continuous technological improvements of all manufacturing processes. This gives us the ability to consistently deliver high quality products to our customers without price increases.

Our ability to provide you a one-stop shop will allow you to save time, money and overhead costs. You will ever only need one supplier which will make everything more efficient and save you a lot of manpower. With one supplier, you will never have anyone pointing fingers at each other. We will be the only ones accountable during the entire process.

As you may know, precision die casting is not an easy task. You must first start with designing the tool that will be used to create your components. Designing and creating the tool is an artform that is very hard to master. The die casting tools that we create can work for around 80,000 shots which is very hard to do. The process to make this tool requires just the right mixtures, designs, and heat treatments to be able to pull this off.

You will also need all the necessary computer tools in order to create tight tolerance precision die-castings. The computer will run a simulation of the whole die casting process allowing you to see the entire process digitally before you start. This roadmap is crucial, allowing you to make any necessary changes before you start the process.

At CIMI, we have the expert design toolmaker on site at all times. We also have state-of-the-art machines including a 5-axis machine center. This means that you will only need to mount the blank once, instead of having the take it out and putting it in a different direction. This machine will minimize any inconsistencies that come from having to mount it multiple times.

Everything is produced in-house so we can ensure the quality and functionalities of our products.

Please call our technical team at CIMI for a quick analysis and pricing for your casting project. You will receive a quote that can most likely save your company money and reduce your overhead.

Please call CIMI’s technical casting team today, in California, at (650) 375-7006.